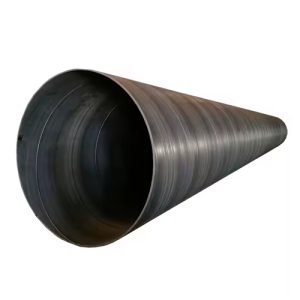

تولید لوله های فولادی اسپیرال

لولههای اسپیرال، معروف به “لوله اسپیرال” به زبان فارسی، به یکی از نقاط اساسی در صنایع مختلف تبدیل شدهاند، با ارائه استحکام، دوام، و کارایی بیهمتا. از تاریخچه جذاب تا فرآیند تولید پیچیده، این لولهها به طور قابل توجهی در بخشهای نفت و گاز، حمل و نقل آب، و سیستمهای تهویه مورد استفاده قرار گرفتهاند.تاریخچه لولههای اسپیرال

تاریخچه لولههای اسپیرال به دههها پیش از امروز بازمیگردد و این محصولات توانستهاند در طول زمان به یکی از ابداعات مهم در عرصه صنعت و ساخت و ساز تبدیل شوند.

لولههای اسپیرال ابتدا به عنوان یک راه حل نوآورانه در زمینه حمل و انتقال مایعات در صنایع مختلف معرفی شدند. ریشههای این فناوری به [منابع] باز میشود که نشانگر استفاده از لولههای این نوع در مواقع زیادی است.

در طی سالیان متمادی، فناوری لولههای اسپیرال تکامل یافت و به روز شد. از ابتدای ساخت و ساز این لولهها تاکنون، مشاهده میشود که فرآیند تولید و طراحی آنها بهبود یافته و با استفاده از مهندسی مدرن و مواد نوین، لولههای اسپیرال به یکی از اجزای اساسی در ساختارهای صنعتی تبدیل شدهاند.

یکی از عوامل کلیدی موفقیت تاریخچه لولههای اسپیرال، توانایی آنها در مقابله با فشارهای بالا و شرایط سخت محیطی بوده است. این لولهها با طراحی خاص اسپیرالی خود، مقاومت و استحکام بیشتری نسبت به لولههای معمولی ارائه میدهند.

با پیشرفت فناوری تولید، مواد مورد استفاده در ساخت لولههای اسپیرال نیز بهبود یافته است. امروزه از فولادهای مقاوم به خوردگی، آلیاژهای مختلف، و حتی پلیمرهای پیشرفته برای ساخت این لولهها استفاده میشود.

به عبارت دیگر، تاریخچه لولههای اسپیرال نه تنها نشانگر گذر از زمان بلکه نماد موفقیت و تکامل در عرصه مهندسی و صنعت است. این لولهها با انعطافپذیری، قدرت، و کارایی درخشان خود، به عنوان یکی از انتخابهای اساسی در پروژهها و صنایع مختلف جایگاه خود را گسترش دادهاند.

ساختار و ترکیب

ساخته شده از [مواد]، طراحی منحصر به فرد اسپیرال این لولهها به استحکام و دوام استثنایی آنها افزوده است. ترکیب [مواد] منجر به تولید محصولی میشود که قادر به تحمل شرایط سختترین است و این انتخاب را در صنایع مورد نظر میکند.

کاربردها در صنعت

لولههای اسپیرال کاربرد وسیعی در [بخش نفت و گاز] دارند و به عنوان یک راه ارتباطی قابل اعتماد برای حمل و انتقال سیالات شناخته میشوند. به علاوه، آنها نقش مهمی در [حمل و نقل آب] و [سیستمهای تهویه] ایفا میکنند و چندگانه بودن آنها در کاربردهای مختلف را نشان میدهد.

مزایای لولههای اسپیرال

مزایای استفاده از لولههای اسپیرال چندگانه هستند. مقاومت در مقابل [خوردگی]، انعطافپذیری، و هزینههای مقرون به صرفه، آنها را به انتخابی مورد علاقه برای صنایعی که به دنبال راهکارهای با دوام و کارآمد هستند، تبدیل کرده است.

فرآیند تولید

فرآیند پیچیده تولید لولههای اسپیرال شامل [مراحل دقیق] است، به طوری که هر قطعه با استانداردهای کیفیت سخت تعیین شده تولید میشود. اقدامات سخت کنترل کیفیت در طول فرآیند تولید به تضمین قابلیت اعتماد محصول نهایی میپردازد.

مقایسه با لولههای سنتی

در مقایسه با لولههای سنتی در زمینههای [قدرت و دوام]، نصب و نگهداری، لولههای اسپیرال از عملکرد برتری برخوردار هستند.

تأثیرات زیستمحیطی

لولههای اسپیرال به لحاظ پایداری در زمینههای محیطزیستی نیز اثرگذار هستند. جنبههای پایداری این لولهها و امکانات [بازیافت] آنها، نشاندهنده تعهد به مسائل محیطی است.

انتخاب صحیح لوله اسپیرال

در انتخاب لوله اسپیرال صحیح، عوامل مختلفی باید در نظر گرفته شوند. این عوامل شامل [مقاومت در برابر خوردگی]، انعطافپذیری و گزینههای [سفارشیسازی] هستند.

مطالعات موردی

موفقیتهایی که در صنایع مختلف با استفاده از لولههای اسپیرال به دست آمده است، نشانگر کارایی و اثربخشی این محصولات در جوانب مختلف است. مثالهای واقعی از کارآمدی و کارایی در دنیای واقعی را مورد بررسی قرار دهید.

چالشها در استفاده از لولههای اسپیرال

علل احتمالی و چالشهای ممکن در استفاده از لولههای اسپیرال را بررسی کرده و راهحلهای ممکن برای کاهش آنها را مطرح کنید. پیشرفت مداوم در طراحی و تولید نیز مورد بررسی قرار گیرد.

روندهای آینده در فناوری لولههای اسپیرال

نگاهی به [نوآوریها] در مواد و تولید لولههای اسپیرال و توقعات احتمالی در کاربردها ارائه دهید.

توصیهنامههای کاربران

نظرات و توصیههای کاربران از صنایعی که از لولههای اسپیرال استفاده کردهاند را معرفی کنید. تجارب مثبت و پیشنهادات آنها را به اشتراک بگذارید.

نکات نگهداری

راهکارها و [نکات نگهداری] جهت اطمینان از دوام و عملکرد لولههای اسپیرال را ارائه دهید. مشکلات رایج و راهحلهای آنها را بررسی کنید.

نتیجهگیری

در ختم مقاله، اهمیت لولههای اسپیرال در صنایع را مرور کرده و صنایع را به کاوش در دنیای فواید آنها تشویق کنید.

به دست آوردن دسترسی به لولههای اسپیرال

برای به دست آوردن دسترسی به لولههای اسپیرال و بهرهمندی از فواید بینظیر آنها، شما میتوانید از لینک زیر استفاده کنید و در دنیای استفاده از تکنولوژی مدرن و پیشرفته قدم بگذارید.

پرسشهای متداول پس از مقاله

1. آیا لولههای اسپیرال قابل بازیافت هستند؟

بله، لولههای اسپیرال قابل بازیافت هستند. این ویژگی آنها را به گزینهای پایدار در زمینه محیطزیست تبدیل میکند.

2. چه عواملی در انتخاب لوله اسپیرال باید در نظر گرفته شوند؟

عواملی مانند مقاومت در برابر خوردگی، انعطافپذیری، و گزینههای سفارشیسازی در انتخاب لوله اسپیرال مهم هستند.

3. آیا لولههای اسپیرال قابلیت سفارشیسازی دارند؟

بله، لولههای اسپیرال قابلیت سفارشیسازی دارند. این امکان به کاربران این امکان را میدهد که محصولات را به تناسب نیازهای خود تغییر دهند.

4. چه مزایایی از استفاده از لولههای اسپیرال در بخش نفت و گاز به دست میآید؟

استفاده از لولههای اسپیرال در بخش نفت و گاز باعث بهبود [عملکرد]، مقاومت در برابر خوردگی، و کاهش هزینهها میشود.

5. چگونه میتوان مشکلات احتمالی در استفاده از لولههای اسپیرال را حل کرد؟

مشکلات احتمالی ممکن است شامل خرابی ساختار، خوردگی، یا ناهماهنگی در نصب باشند. برای حل این مسائل، نیاز به [نگهداری منظم] و استفاده از مواد با کیفیت داریم.