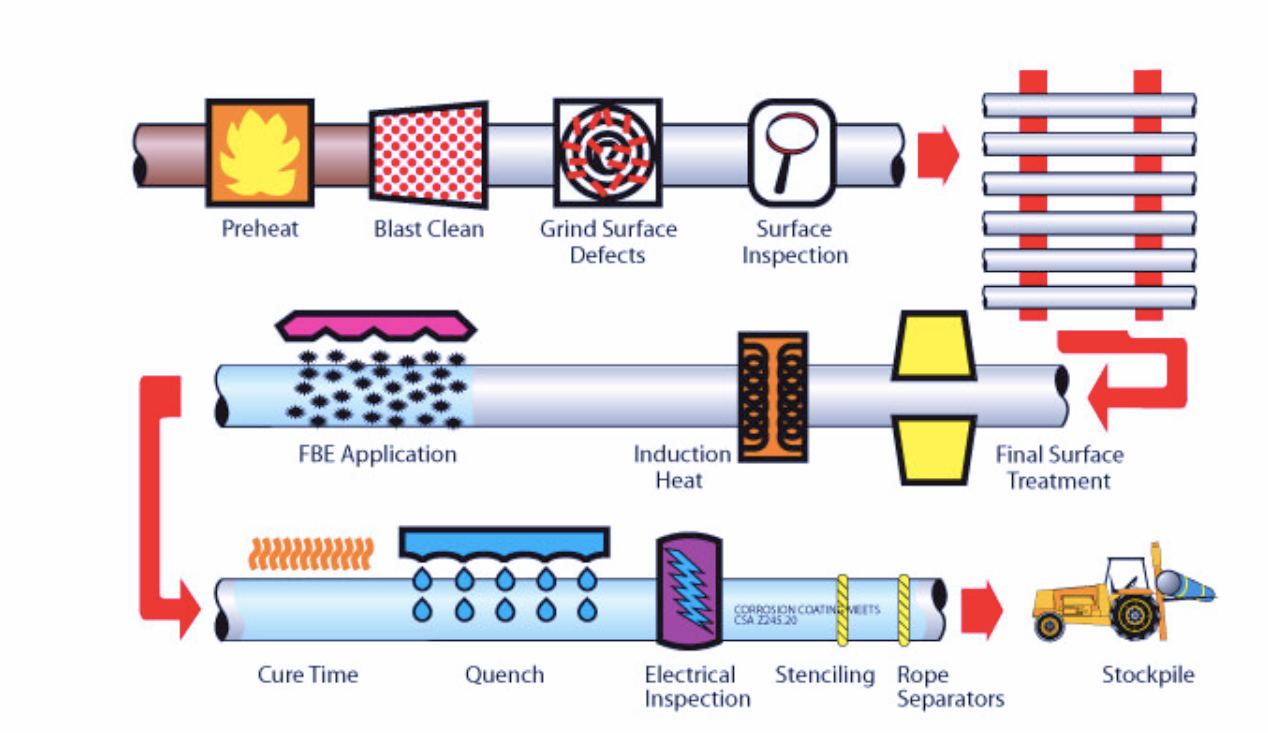

Surface Preparation – Pipes undergo preheating and shot blasting to remove impurities and enhance adhesion.

Primer Application – A base primer layer is applied to optimize the bonding of protective coatings.

Main Coating Application – Depending on the project, Neyzar applies 3LPE, FBE, bitumen enamel, or polyurethane coatings, ensuring durability and corrosion resistance.

Curing & Quality Control – The coated pipes undergo controlled curing before rigorous inspection, thickness measurement, and adhesion tests.

Final Inspection & Delivery – Each pipe is visually checked, tested for uniformity, and prepared for export worldwide with premium packaging.

Neyzar ensures top-tier quality & innovation in every pipeline project.