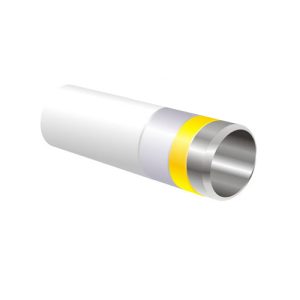

Internal and external coating of steel pipes

Internal and external coatings of steel pipes can serve as an excellent protection against corrosion and other damage. These coatings can be tailored to different needs depending on the type of application and the surrounding environment of the pipe.

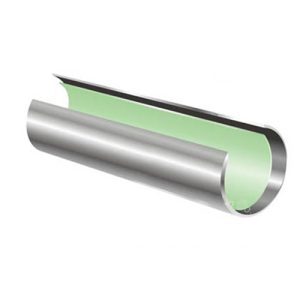

Internal Coating:

• Epoxy: To prevent internal corrosion and increase corrosion resistance.

• Polyamide: To reduce friction and increase flexibility.

• Special Antibacterial Coatings: For special applications such as water tank pipes.

External Coating:

• Epoxy Coating: To combat corrosion, rust, and protect against atmospheric agents.

• Polyurethane: To increase mechanical strength and corrosion resistance.

• Decorative Coatings: For use in projects where aesthetics are also important.

Each coating may be selected based on specific environmental conditions and project needs.

Specialized External Coatings:

• Fire-Resistant Coatings: For heat resistance and protection in emergency situations.

• UV-Resistant Coatings: To combat the harmful effects of ultraviolet rays.

• Anti-Corrosion Coatings: To protect the pipe from the effects of corrosion and rust.

• Aluminum Coatings: To increase corrosion resistance and protect the pipe in certain environments.

Each of these coatings is selected depending on the physical, chemical, and environmental characteristics of the pipes. These choices are made to protect the steel pipes against various environmental conditions and ensure long life and optimal performance.

Anti-Corrosion Coatings:

• Homogeneous Coatings: These coatings are usually composed of stainless steel and can provide excellent corrosion resistance.

• Anodic Phosphate Coating: To increase corrosion resistance and increase adhesion of subsequent coatings.

Heat Resistant Coatings:

• Resin Coatings: To resist high temperatures and thermal effects.

• Ceramic Coatings: To resist heat and fire.

• Solar Reflective Coatings: To reduce heat absorption from solar radiation and reduce temperature rise.

Note that the selection of the appropriate coating depends on the type of environment (aquatic, oceanic, industrial, terrestrial) and environmental conditions (temperature, pressure, density). It is also recommended to be done according to the specific needs of the project and advice from industrial specialists and materials engineers.